AIR ASPIRATORS

Grain dust aspirators work on the principle of different speeds of particle spinning, depending on their weight and size. This can easily be represented by the example of an aerodium, in which air is pumped up and down, and a person flies in weightlessness. If you drop a stone and a ball of the same size into this pipe of the airdrome, then the stone will fall down, and the ball will be carried upward by a stream of air. The same difference in weight is the grain and light admixture (straw, bran, dust, etc.). By analogy, the grain, like the stone, will fall down, and the lighter impurities, like a ball, will fly away upwards.

For effective work of the dust aspirator, it is necessary to feed the grain with an even thin layer several grains thick, which requires a sufficiently wide plane of grain flow. The maximum efficiency is achieved with a vertical air supply in the countercurrent to the grain. Therefore, small-size aspirators with air supply from the side are ineffective.

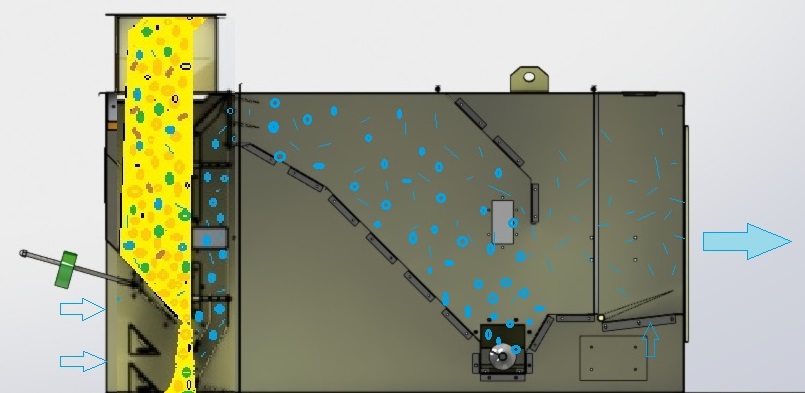

The determining role is played by the amount of blown air per unit mass of grain. Practice shows that for optimal cleaning of 1 ton of grain per hour, it is necessary not less than 45-50 cubic meters of air at a certain rate. To prevent the entrainment of the grain itself, along with the dust, it is necessary to reduce the air flow rate at the grain blowing site without reducing its volume. For this purpose, an extended and elongated dust receptacle is connected to the pipe or to the fan. To collect dust and waste, a cyclone or filter is installed.

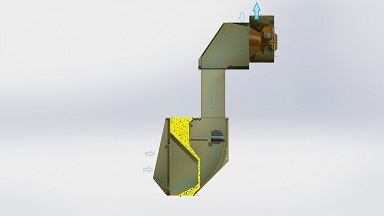

In the flow aspirators MAROT of BD series, all the above-mentioned nuances are taken into account, as well as the possibility of adjusting the air flow and adjusting the grain layer. This allows you to regulate the efficiency of cleaning both dry and wet grain. This type of aspirator is installed directly in the grain flow (in gravity, in front of the noria or conveyor, etc.).

In the pre-cleaning aspirators of the MAROT series A, after the grain is blown, the waste is divided into fractions of different severity. In the middle of the cleaning process, heavier impurities settle and are discharged by the auger, and the lighter passes through the cyclone or filter, which significantly increases the efficiency of the equipment and facilitates further air purification from the dust in the cyclone or filter. This type of aspirator is installed either as a separate unit in the flow, or in combination with a cleaner.

AGRO PROFF also offers closed-loop aspirators where air re-circulation is used, which is cleaned in the built-in cyclone and fed back to purge the grain flow. Such devices are more spacious and quite expensive.